Last Updated on 4 months by Francis

Have you ever wondered how light bulbs work? We often associate them with providing bright and visible light, but did you know that there’s more to it? Infrared radiation, a form of electromagnetic radiation, plays a crucial role in the technology behind light bulbs.

Infrared light bulbs, also known as infrared lamps, are electrical devices that emit infrared radiation. They are widely used in various applications such as heating, communication, scientific research, and industrial processes. While we primarily think of light bulbs as sources of visible light, they also generate infrared radiation as a byproduct.

Incandescent light bulbs, for example, use a tungsten filament that produces both visible light and infrared radiation. This is why incandescent bulbs can feel warm to the touch. Additionally, infrared light-emitting diodes (LEDs) are specifically designed to emit near-monochromatic infrared energy, making them efficient sources of infrared radiation for different purposes.

Understanding the role of infrared radiation in light bulb technology can enhance our knowledge of their applications and efficiency. Let’s delve deeper into the fascinating world of infrared lamps and their diverse uses.

Contents

Key Takeaways

- Light bulbs, such as incandescent bulbs, produce infrared radiation in addition to visible light.

- Infrared lamps are used for heating, communication, industrial processes, and scientific research.

- Infrared light-emitting diodes (LEDs) are efficient sources of near-monochromatic infrared energy.

- Infrared radiation is harnessed for various applications, including heating, communication, and curing coatings.

- Efficient thermal management is crucial for maximizing the performance and lifespan of infrared lamps and LED lighting solutions.

Types of Infrared Lamps

When it comes to infrared lamps, there are different types available, each serving different purposes and applications. Let’s take a closer look at some of these types:

1. Incandescent Light Bulbs

Incandescent light bulbs are a common type of infrared lamp. They use a tungsten filament that emits visible light as well as infrared radiation. These bulbs produce heat, making them useful for various applications that utilize the generated heat. Some examples include:

- Incubators

- Reptile tanks

- Novelty lamps

- Heat lights for reptiles

2. Quartz Halogen Linear Lamps

Quartz halogen linear lamps are designed to provide higher power density, making them suitable for industrial heating applications. These lamps offer precise control over the distribution of heat, allowing for efficient and targeted heating in industrial processes.

3. Infrared LEDs

Infrared LEDs (Light-Emitting Diodes) are a specialized type of infrared lamp used for communication and control signals. They emit infrared radiation in the near-mid range of the infrared spectrum. Infrared LEDs are commonly found in applications such as:

- Remote controls

- Infrared data transmission (IrDA)

- Proximity sensors

Please note that the examples listed above are not an exhaustive list of applications and uses for each type of infrared lamp.

Now that we understand the different types of infrared lamps, let’s explore their applications in more detail in the upcoming sections.

Infrared Heating

Infrared heating is an innovative method that utilizes heat lamps to transmit therapeutic infrared radiation, providing numerous applications and benefits. This type of heating is widely used in industrial processes, building heating, and even household applications. Let’s explore how infrared heating works and its various uses.

Radiant Heating with Heat Lamps

Infrared heating operates on the principle of radiant heat transfer. Heat lamps emit infrared radiation that directly heats objects and surfaces without warming the surrounding air. This efficient method of heat distribution eliminates energy wastage, making it a cost-effective and environmentally friendly heating solution.

Unlike conventional heating systems that rely on convection to warm the air, infrared heating ensures a comfortable and consistent temperature throughout the space. It creates a cozy and relaxing environment by eliminating cold spots and drafts.

One practical use of infrared heating is in bathrooms, where heat lamps provide instant warmth without having to wait for the entire room to heat up. They are also used for heating pets’ living areas, ensuring their comfort during colder seasons.

Applications in Coating Curing and Cooking

Infrared heating is widely employed in the industrial sector for curing coatings. The focused infrared radiation generated by heat lamps accelerates the drying and hardening process of various coatings such as paint, varnish, and powder coating. This leads to improved productivity and reduced waiting times in manufacturing processes.

Cooking is another area where infrared heating finds extensive use. Infrared heat lamps are utilized in food preparation to provide a quick and efficient cooking method. They are particularly effective in browning and crisping food surfaces, giving dishes a delightful texture and appearance.

Whether in professional kitchens or home cooking, the controlled heat emission of infrared lamps ensures consistent cooking results with reduced cooking times. This makes them a valuable tool for chefs and cooking enthusiasts.

Additionally, infrared heating is also utilized in specialized cooking equipment, such as broilers, grills, and toasters, to deliver optimal cooking performance and achieve desired culinary outcomes.

A Table Demonstrating the Applications of Infrared Heating

| Application | Description |

|---|---|

| Curing Coatings | Accelerates the drying and hardening process of various coatings in industrial manufacturing. |

| Cooking | Efficiently cooks and browns food, providing quick and consistent results. |

| Building Heating | Provides efficient and comfortable heating in spaces, eliminating cold spots and drafts. |

| Bathroom Heating | Delivers instant warmth without requiring the entire room to heat up. |

| Pet Heating | Ensures the well-being and comfort of pets during colder seasons. |

As demonstrated in the table above, infrared heating offers a versatile range of applications, from industrial coating processes to everyday cooking and household heating needs. The efficiency and effectiveness of heat lamps in delivering infrared radiation make them a valuable technology in various domains.

Next, we’ll delve into the world of infrared communication and explore how this technology enables short-range wireless data transfer.

Infrared Communication

Infrared light plays a vital role in short-range communication among computer peripherals and personal digital assistants. This mode of communication uses infrared radiation, and the devices adhere to the standards set by the Infrared Data Association (IrDA).

Devices such as remote controls and IrDA devices utilize infrared light-emitting diodes (LEDs) to emit focused beams of infrared radiation. The receiver, on the other hand, relies on a silicon photodiode to convert the received infrared radiation into an electric current.

Infrared communication is predominantly used for indoor applications and offers the advantage of not interfering with other devices in adjoining rooms.

Applications of Infrared Lamps

Infrared lamps offer a wide range of applications that cater to various industries and needs. Let’s explore some of the key uses of these versatile lamps:

Animal Heat Lamps

Animal heat lamps are commonly used in incubators and reptile tanks to provide the optimum temperature for reptiles, birds, and other small animals. These lamps emit infrared radiation that mimics the warmth of natural sunlight, creating a comfortable and nurturing environment for the animals.

Catering Heat Lamps

Catering heat lamps are essential for keeping food warm and maintaining its quality during events and gatherings. These lamps emit a gentle heat that keeps the food at the desired serving temperature, ensuring that it remains delicious and appetizing for extended periods.

Heat Lamps for Plants

Plants require specific temperature conditions to thrive, especially in controlled environments such as greenhouses. Heat lamps for plants help regulate the temperature, providing the necessary warmth for optimal growth. These lamps ensure consistent heat distribution, promoting healthy plant development and increasing overall productivity.

Infrared Paint Curing Lamps

Infrared paint curing lamps are widely used in the automotive industry and other sectors where fast and efficient drying and hardening of paint is crucial. These lamps emit a focused beam of infrared radiation that accelerates the curing process, reducing production time and enhancing the durability of painted surfaces.

Medical Uses

The therapeutic benefits of infrared radiation have led to its use in various medical applications. Infrared heat lamps are frequently employed to soothe joints and muscles, providing relief from pain and promoting relaxation. These lamps emit a gentle warmth that penetrates deep into the tissues, encouraging healing and enhancing overall well-being.

Take a look at the table below for a summary of the applications of infrared lamps:

| Application | Description |

|---|---|

| Animal Heat Lamps | Provide optimal warmth for incubators and reptile tanks |

| Catering Heat Lamps | Keep food warm and maintain its quality during events |

| Heat Lamps for Plants | Regulate temperature in greenhouses for optimal plant growth |

| Infrared Paint Curing Lamps | Accelerate drying and hardening of paint in the automotive industry |

| Medical Uses | Soothe joints and muscles for pain relief and relaxation |

From providing warmth to animals and keeping food deliciously warm at catered events, to promoting healthy plant growth and curing paint efficiently, as well as offering therapeutic benefits in the medical field, infrared lamps have a wide range of practical applications. Their versatility and effectiveness make them an invaluable tool in various industries and settings.

Efficiency of Infrared Bulbs

When it comes to the efficiency of infrared bulbs, there are several factors to consider. Incandescent bulbs, for example, produce a significant amount of infrared radiation but only a small percentage of visible light output. On the other hand, LEDs (Light Emitting Diodes) have a different performance profile. They produce more visible light and generate less heat compared to incandescent bulbs.

The efficiency of an infrared bulb is determined by various factors, including power density, visible light output, and the lifetime of the bulb. Power density refers to the amount of power emitted per unit area, and it affects the intensity of the infrared radiation produced. Visible light output is essential as well since it determines the amount of usable light emitted by the bulb.

Additionally, the lifetime of the bulb is a crucial consideration. The longer the bulb lasts, the more efficient it is in terms of longevity and maintenance costs. LED bulbs, for instance, generally have a longer lifespan compared to incandescent bulbs, making them a more efficient choice in the long run.

By combining high power density, optimal visible light output, and a long lifetime, infrared bulbs can provide efficient and effective lighting solutions for various applications.

| Factors | Efficiency Impact |

|---|---|

| Power Density | Affects the intensity of infrared radiation |

| Visible Light Output | Determines the amount of usable light emitted |

| Lifetime | The longer the bulb lasts, the more efficient it is in terms of longevity and maintenance costs |

Infrared bulbs can provide efficient lighting solutions by balancing power density, visible light output, and lifespan. Understanding the factors that contribute to the efficiency of these bulbs allows for informed decision-making when it comes to selecting the right lighting option for various applications.

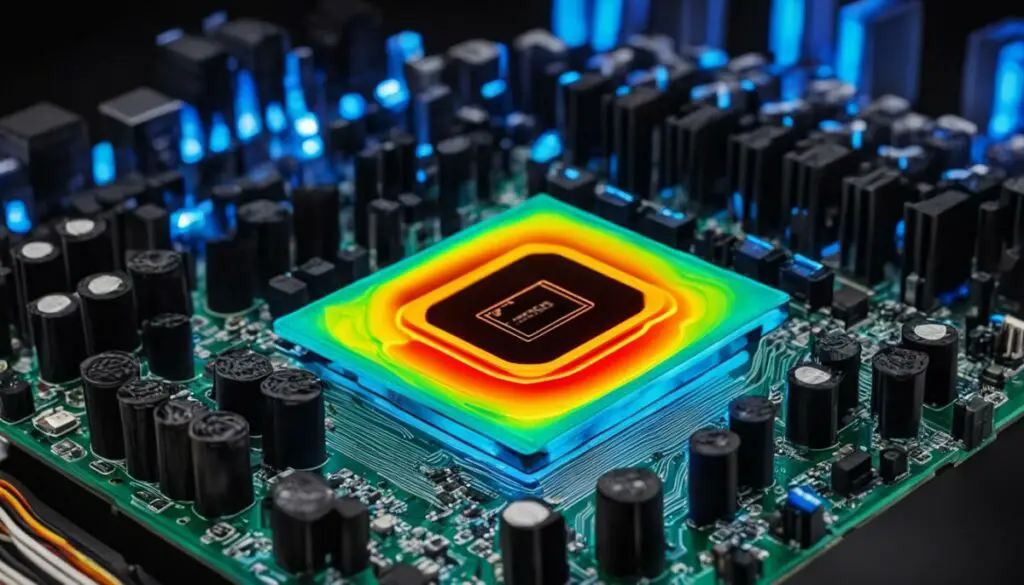

Importance of Thermal Management for LEDs

Effective thermal management is crucial for maximizing the performance and extending the lifespan of LEDs. The junction temperature of an LED is a key factor that directly impacts its characteristics, including forward voltage, lumen output, and wavelength. In order to maintain optimal performance, it is essential to implement good thermal management strategies.

Why Thermal Management Matters

LEDs generate heat during operation, and if not properly managed, this heat can significantly impact their performance and longevity. Excessive heat can cause thermal stress on the LED junction, leading to a decrease in efficiency and even premature failure. By implementing effective thermal management techniques, the junction temperature can be controlled, ensuring the LED operates within its specified limits for optimal performance and extended lifetime.

Minimizing Thermal Resistance

One key aspect of thermal management is minimizing thermal resistance within the LED system. Thermal resistance limits the flow of heat and can cause the junction temperature to rise. To reduce thermal resistance, it is important to optimize the thermal path, ensuring efficient heat transfer away from the LED junction.

“Proper thermal management involves using materials with high thermal conductivity to conduct heat away from the LED junction, optimizing heat transport, and minimizing thermal resistance.”

Optimizing Heat Dissipation

Effective heat dissipation is another critical factor in thermal management for LEDs. Heat sinks, such as metallic fins or heat pipes, can be used to efficiently dissipate heat away from the LED junction. These heat sinks increase the surface area available for heat transfer, allowing for better heat dissipation and reducing the junction temperature.

Thermal Conductivity and Materials

The choice of materials used in the LED system can also play a significant role in thermal management. Materials with high thermal conductivity, such as copper or aluminum, are effective in conducting heat away from the LED junction. By optimizing the thermal conductivity of the materials used, the overall thermal resistance can be reduced, improving the efficiency and performance of the LED.

Benefits of Effective Thermal Management

- Extended LED lifetime: By maintaining the junction temperature within the recommended limits, the lifespan of the LED can be significantly extended.

- Consistent performance: Effective thermal management ensures that the LED operates consistently, maintaining its output and color quality over time.

- Better energy efficiency: By reducing thermal resistance and optimizing heat dissipation, the overall energy efficiency of the LED system can be improved.

- Reliability and durability: Proper thermal management helps prevent thermal stress and premature failure, ensuring the long-term reliability and durability of the LED.

| Thermal Management Techniques | Benefits |

|---|---|

| Use of heat sinks | Enhanced heat dissipation and reduced junction temperature |

| Optimization of thermal path | Efficient heat transfer away from the LED junction |

| Utilization of materials with high thermal conductivity | Improved heat conduction and reduced thermal resistance |

Optimizing Heat Transfer in LED Fixtures

To ensure optimal performance and reliability of LED fixtures, it is crucial to optimize heat transfer and effectively manage thermal resistance. Creating an efficient thermal path for heat to escape from the LED junction is a fundamental aspect of this optimization process.

One key strategy is to use materials with high thermal conductivity. These materials act as efficient conduits, allowing heat to flow away from the LED junction and dissipate into the surrounding environment. By choosing the right materials, such as aluminum or copper, heat transfer can be significantly improved.

Another approach is to reduce the number of interfaces within the LED fixture. Each interface introduces additional thermal resistance, hindering the flow of heat. By minimizing the interfaces and ensuring tight connections between components, thermal resistance can be minimized, allowing for more efficient heat transfer.

Maximizing heat sinking is also crucial in optimizing heat transfer. Heat sinking involves the use of dedicated heat sinks, which are designed to efficiently dissipate heat away from the LED fixture. These heat sinks can be made of materials with high thermal conductivity or feature intricate designs that increase the surface area for heat dissipation.

“Efficient heat transfer is essential for maximizing the performance and lifetime of LED fixtures.”

In addition to materials and heat sinking, ensuring efficient convection is vital for effective heat dissipation. Convection allows for the transfer of heat between the LED fixture and the surrounding air. By incorporating proper airflow within the fixture design and considering natural convection or forced-air cooling, heat transfer can be optimized.

By implementing these strategies and optimizing heat transfer, LED fixtures can operate at lower temperatures, reducing the risk of thermal damage and maximizing their lifespan. They can also maintain their performance levels, ensuring consistent and reliable lighting output.

Overall, proper thermal management and optimization of heat transfer play a significant role in maximizing the efficiency and longevity of LED fixtures. By providing a thermal path, using high thermal conductivity materials, minimizing thermal resistance, and incorporating efficient heat sinking and convection, LED fixtures can deliver superior performance and reliability.

Calculating Thermal Resistance

Thermal resistance is a crucial factor in determining the performance and lifespan of LED lighting solutions. It quantifies the change in temperature difference between two points for every watt of input power. By calculating thermal resistance, we can estimate the junction temperature of the LED under different operating conditions, allowing us to predict its lifetime.

To calculate thermal resistance, we need to consider the individual thermal resistances and their sum from the LED junction to ambient. These resistances include:

- LED package thermal resistance

- Thermal resistance between the LED package and the heat sink

- Thermal resistance within the heat sink

- Thermal resistance between the heat sink and the ambient environment

The total thermal resistance can be determined using the following formula:

Overall Thermal Resistance = LED Package Thermal Resistance + Thermal Resistance (LED Package to Heat Sink) + Thermal Resistance (Heat Sink) + Thermal Resistance (Heat Sink to Ambient)

Once we have calculated the thermal resistance, we can estimate the junction temperature of the LED based on the input power and the ambient temperature. This information plays a crucial role in ensuring the optimal performance and longevity of LED fixtures.

Let’s consider an example: a 10-watt LED with a thermal resistance of 5°C/W and an ambient temperature of 25°C. Using the formula, we can estimate the junction temperature:

Junction Temperature = Ambient Temperature + (Input Power × Overall Thermal Resistance)

Substituting the values from our example:

Junction Temperature = 25°C + (10W × 5°C/W) = 75°C

Based on this estimation, we can make informed decisions about the heat sinking and thermal management strategies required to ensure the LED operates within its specified temperature limits and achieves its expected lifetime.

Example Calculation of Junction Temperature

| LED Power (W) | Overall Thermal Resistance (°C/W) | Ambient Temperature (°C) | Junction Temperature (°C) |

|---|---|---|---|

| 5 | 3 | 30 | 75 |

| 10 | 5 | 25 | 75 |

| 15 | 7 | 35 | 140 |

Fixture Performance and Thermal Considerations

The performance and longevity of LED fixtures are directly influenced by their thermal characteristics. Effective thermal management is essential to ensure optimal fixture performance and prevent long-term issues. Several key factors must be considered in fixture design to address thermal considerations, particularly for IP-rated fixtures.

IP-rated fixtures are designed to provide protection against dust, water, and other environmental elements. While this design feature is advantageous, it can also pose challenges to heat transfer. Without efficient heat sinking, excess heat can build up inside the fixture, compromising its performance and durability.

To overcome this challenge, it is crucial to implement effective heat transfer mechanisms within the fixture design. This can involve the use of materials with high thermal conductivity, such as aluminum or copper, to facilitate the transfer of heat away from the LED source.

Furthermore, the design should minimize the number of interfaces and maximize the thermal path between the LED junction and the external environment. By reducing thermal resistance and optimizing heat conduction, the fixture can efficiently dissipate heat, ensuring the LED operates at acceptable temperatures.

In addition to heat sinking, the overall thermal management of the entire system should be taken into account. This includes the placement of the fixture, the surrounding environment, and the potential for heat accumulation. Through thoughtful consideration of these factors, the fixture can be positioned and designed to maximize heat dissipation.

| IP-Rated Fixtures | Non-IP-Rated Fixtures | |

|---|---|---|

| Heat Transfer | Challenging due to limited airflow | Easier due to open design |

| Material | Materials with high thermal conductivity required | Less emphasis on thermal conductivity |

| Thermal Resistance | Higher thermal resistance due to enclosure | Lower thermal resistance |

| Placement | Consideration of heat accumulation and dissipation | Placement less critical for heat management |

Note: The table above provides a comparison between IP-rated fixtures and non-IP-rated fixtures regarding thermal considerations. IP-rated fixtures have additional challenges due to limited airflow and higher thermal resistance, requiring careful attention to heat transfer mechanisms.

By adequately addressing thermal considerations in fixture design, LED fixtures can operate at optimal efficiency and longevity. Effective heat transfer mechanisms, such as proper heat sinking and thermal path optimization, are crucial for maintaining ideal operating temperatures. With thorough thermal management, LED fixtures can deliver exceptional performance while minimizing the impact of heat on overall fixture reliability.

Conclusion

In conclusion, the role of infrared radiation in light bulb technology is diverse and wide-ranging. It is utilized in various applications such as heating, communication, curing coatings, and even medical treatments. Infrared lamps, including incandescent bulbs and LEDs, emit both visible light and infrared radiation, making them versatile tools for different purposes.

However, efficient thermal management is crucial for maintaining the performance and longevity of LED fixtures. Proper heat transfer and convection are essential to maximize the efficiency and lifespan of infrared lamps and LED lighting solutions. By optimizing heat sinking and minimizing thermal resistance, the overall thermal management of the system can be improved, ensuring optimal fixture performance.

Understanding the significance of infrared radiation and implementing effective thermal management techniques can lead to advancements in light bulb technology. From energy-efficient lighting solutions to innovative heating applications, the future of infrared radiation in the realm of light bulbs holds great promise. As technology continues to evolve, so too will our ability to harness the full potential of infrared radiation in the field of light bulb technology.

FAQ

Are light bulbs powered by infrared radiation?

Light bulbs, such as incandescent bulbs, produce both visible light and infrared radiation. However, they are primarily powered by electrical energy.

What are infrared light bulbs?

Infrared light bulbs are electrical devices that emit infrared radiation along with visible light. They are used in various applications, including heating, communication, curing coatings, and medical uses.

How do light bulbs work?

Light bulbs, like incandescent bulbs, use a tungsten filament to produce visible light and infrared radiation when an electric current passes through them. LEDs, on the other hand, utilize a different mechanism to generate light.

What are the different types of infrared lamps?

There are various types of infrared lamps, including incandescent light bulbs, quartz halogen linear lamps, and infrared LEDs. Each type has different applications and characteristics.

How is infrared heating used?

Infrared heating utilizes heat lamps that emit infrared radiation for applications such as curing coatings, cooking, and providing heat in bathrooms and for pets. It is an efficient and focused heating method.

What is infrared communication?

Infrared communication involves the use of infrared light for short-range communication, commonly seen in devices like remote controls. Infrared light-emitting diodes emit the infrared radiation, which is then converted into an electric current by a receiver.

What are the applications of infrared lamps?

Infrared lamps have a wide range of applications, including animal heat lamps for incubators and reptile tanks, catering heat lamps for food warming, heat lamps for plants, and infrared paint curing lamps. They are also used for medical purposes in soothing joints and muscles.

How efficient are infrared bulbs?

The efficiency of an infrared bulb depends on factors like power density, visible light output, and the bulb’s lifetime. Incandescent bulbs produce a significant amount of infrared radiation but are less efficient than LEDs, which generate more visible light and less heat.

Why is thermal management important for LEDs?

Thermal management is crucial for LEDs to maintain their performance and longevity. The junction temperature of an LED affects its characteristics, and proper heat dissipation ensures optimal performance and reliability.

How can heat transfer be optimized in LED fixtures?

Heat transfer in LED fixtures can be optimized by using materials with high thermal conductivity, reducing thermal resistance between mating surfaces, and ensuring efficient convection for heat dissipation. Proper heat sinking is also important for long-term performance.

How is thermal resistance calculated?

Thermal resistance is calculated by measuring the change in temperature difference between two points for each watt of input power. The total thermal resistance is the sum of individual resistances, allowing for the estimation of LED junction temperature under different operating conditions.

What should be considered for fixture performance and thermal considerations?

Fixture performance should consider efficient heat transfer, especially for IP-rated fixtures that can trap heat inside. Proper thermal management of the entire system is essential to ensure optimal fixture performance and longevity.

What role does infrared radiation play in light bulb technology?

Infrared radiation plays a significant role in light bulb technology, with applications ranging from heating and communication to curing coatings and medical uses. Efficient thermal management ensures the longevity and performance of infrared lamps and LED lighting solutions.

.jpg)