Last Updated on 10 months by Francis

.jpg)

LED work lights are versatile and efficient lighting solutions commonly used in various industries and applications. While they offer numerous benefits, such as low energy consumption and long lifespan, the question arises: do LED work lights need a relay? In this article, we will explore the role of relays in LED work lights and why they are commonly used. We will also discuss the factors to consider in determining if a relay is needed for your specific setup.

We will delve into the benefits of using a relay with LED work lights, including enhanced performance and longevity. Whether you are a professional using LED work lights for your job or an enthusiast incorporating them into your vehicle or home, understanding the need for relays can help you make informed decisions for optimal functionality and safety.

Contents

Key takeaway:

- Enhanced Performance and Efficiency: The use of a relay in LED work lights improves their performance and efficiency, ensuring optimal power management and safety.

- Longevity of the LED Work Lights: Incorporating a relay helps protect the switch and extends the lifespan of the LED work lights, making them more durable and reliable.

What is a Relay?

Photo Credits: Infraredforhealth.Com by Justin Davis

A relay is an electrical device that controls the flow of power to another device or circuit. It works by using an electromagnetic switch to open or close the circuit based on the input it receives. Relays are often used to control high-power devices or circuits using a low-power signal.

The purpose of a relay is to provide isolation and protection for sensitive electronics. It prevents damage to the control circuit by separating it from the high-power circuit, allowing a small control signal to control a larger load.

Relays are commonly used in automotive applications, such as controlling headlights or other electrical components. They are also used in industrial settings, where they can control motors, fans, or other high-power equipment.

When choosing a relay, it is important to consider factors such as the voltage and current ratings, the type of control signal needed (such as AC or DC), and the switching speed required. Relays come in different sizes and configurations to meet the specific needs of different applications.

What is a Relay?

How Does a Relay Work?

A relay is an electrically operated switch that uses an electromagnet to control the flow of current in a circuit. So, how does a relay work? When power is applied to the coil of the relay, it creates a magnetic field that attracts a movable contact, causing it to close or open the circuit. This allows a small current to control a larger current or voltage, providing a way to switch high-power devices with a low-power control signal.

The coil of the relay is typically controlled by a switch or an electronic circuit. When the control signal is activated, it energizes the coil, which then switches the contacts of the relay. This can be used to turn on or off other devices or components in the circuit.

Relays are commonly used in LED work lights for various reasons. They help in power management and safety by allowing the use of a lower current control signal to switch on or off high-power LED lights. They also protect the switch, preventing it from being damaged by high current or voltage.

Additionally, relays contribute to extending the lifespan of LED work lights by reducing the load on the switch and improving overall efficiency. By using a relay, the LED lights are isolated from the control circuit, preventing any potential voltage spikes or fluctuations from affecting the lights directly.

Why are Relays Used in LED Work Lights?

Discover the fascinating world of relays and their crucial role in LED work lights. Join us on this journey as we uncover the reasons behind using relays in these powerful lighting solutions. From ensuring power management and safety to protecting the switches and extending the lifespan of LED work lights, we’ll explore the various aspects of relay usage in this illuminating section. Get ready to dive into the mechanics and benefits that make relays an essential component in LED work lights.

Power Management and Safety

Power management and safety are of utmost importance when it comes to the utilization of LED work lights. Ensuring effective power management is vital to guarantee optimal and efficient functioning of the lights. This involves the regulation of voltage to maintain a stable power supply, thereby preventing any potential damage to the lights and enhancing their durability. Furthermore, proficient power management aids in the prevention of overheating, consequently reducing the risk of fire hazards.

Safety measures are also a critical component of power management. Protective mechanisms are necessary to avert electrical accidents or short circuits when using LED work lights. The inclusion of a relay is crucial in providing this protection as it enables isolation between the power source and the light, thereby minimizing the risk of electrical shock or damage.

The use of a relay that is appropriately sized helps in managing the power flow, ensuring that the LED work lights operate within their designated safe power limits. This not only aids in preventing overload on the electrical system but also becomes particularly significant in vehicles where the wiring and electrical components may not be designed to handle the high power demands of the lights.

Protecting the Switch

To ensure the protection of the switch in LED work lights, follow these steps:

- Make sure that the switch is rated for the voltage and current of the LED work lights.

- Inspect the switch for any indications of wear or damage. If necessary, replace it.

- To handle the high electrical load, install a relay between the switch and the LED work lights.

- Connect the switch to the relay’s control terminals using appropriate wires and connectors.

- To safeguard the switch and relay against overload or short circuits, use a fuse or circuit breaker.

Fact: By reducing the electrical load it needs to handle, using a relay can significantly enhance the lifespan of the switch in LED work lights.

Extending the Lifespan of LED Work Lights

To extend the lifespan of LED work lights and ensure reliable performance for your work needs, follow these steps:

1. Clean regularly: Remove dust, dirt, and debris from the surface of the lights using a soft, non-abrasive cloth or brush. This helps prevent buildup and ensures optimal performance.

2. Avoid overloading: Do not exceed the recommended wattage or power limit for your LED work lights. Overloading can cause strain on the components and shorten their lifespan.

3. Use surge protection: Invest in surge protectors or voltage regulators to protect the LED work lights from power surges or fluctuations that can damage the internal circuitry.

4. Proper cooling: Ensure that LED work lights have proper ventilation and are not placed in areas where excessive heat can build up. Overheating can reduce the lifespan of the lights.

5. Choose high-quality products: Opt for LED work lights from reputable brands known for their durability and quality. High-quality lights are built to withstand tough conditions and have a longer lifespan.

6. Follow manufacturer’s instructions: Read and adhere to the manufacturer’s guidelines and recommendations for installation, operation, and maintenance of the LED work lights.

7. Inspect and replace faulty parts: Regularly check the lights for any signs of damage or wear. Replace any faulty or damaged components promptly to prevent further issues and extend the overall lifespan of the lights.

Do LED Work Lights Need a Relay?

Photo Credits: Infraredforhealth.Com by Peter Young

When it comes to LED work lights, one question often arises: do they need a relay?

In this section, we’ll dive into the importance of using a relay with LED work lights and explore the factors that should be considered.

Get ready to uncover the secrets behind optimizing the performance and longevity of your LED work lights.

No more guesswork – we’ll provide you with the insights you need to make an informed decision.

Let’s shed some light on this topic!

The Importance of Using a Relay

Using a relay is crucial when it comes to LED work lights. The importance of using a relay lies in several key factors.

Firstly, a relay helps with power management and safety. It acts as a switch that controls the flow of electricity to the LED work lights, preventing any potential overloading or short circuits. This ensures that the lights operate at optimum levels without any risk of damage or safety hazards.

Secondly, a relay plays a vital role in protecting the switch. By utilizing a relay, the electrical load is redirected away from the switch, preventing it from being subjected to high currents. This helps to extend the lifespan of the switch and ensures its reliable operation over time.

Lastly, using a relay enhances the longevity of the LED work lights themselves. By regulating the power supply and preventing any electrical fluctuations, the relay helps to maintain stable and consistent performance, resulting in longer-lasting lights with improved durability.

Factors to Consider

| Factors to Consider |

| 1. Power and Wattage of the LED Work Light: When deciding on an LED work light, it is crucial to consider the power requirements and wattage. It is essential to choose a relay that can handle the power load to prevent any electrical issues. |

| 2. Length and Gauge of the Wiring: The length and gauge of the wiring used in the LED work light setup should be taken into account. In cases of longer wiring, a relay is necessary to ensure proper voltage distribution and prevent voltage drops. |

| 3. Vehicle’s Electrical System: Evaluating your vehicle’s electrical system is vital. If your vehicle has a low-amp or old wiring system, using a relay can safeguard the system from damage and guarantee the optimal functioning of the LED work lights. |

Considering these factors to consider will assist you in determining whether a relay is necessary for your LED work lights. It is crucial to make an informed decision to ensure the safety, efficiency, and longevity of both your LED work lights and the overall electrical system.

How to Determine if a Relay is Needed?

Are you unsure if your LED work lights need a relay? Don’t worry, we’ve got you covered! In this section, we will dive into the factors that can help you determine if a relay is necessary. From the power and wattage of the LED work light to the length and gauge of the wiring, as well as your vehicle’s electrical system and the longevity of the LED work lights themselves, we’ll explore all the key considerations. Get ready to make an informed decision that will optimize the performance of your LED work lights!

Power and Wattage of the LED Work Light

When considering the power and wattage of the LED work light, it is important to assess the specific requirements for your lighting needs. The power consumption and wattage of LED work lights can vary depending on the model and purpose of use.

| LED Work Light | Power Consumption (Watts) |

| Model A | 50 Watts |

| Model B | 100 Watts |

| Model C | 150 Watts |

When selecting the power and wattage of the LED work light, consider the specific tasks or environments in which the light will be used. Higher wattage lights are suitable for larger work areas or situations that require brighter illumination. Lower wattage lights may be sufficient for smaller projects or tasks that do not require intense lighting.

It is crucial to always check the power supply and ensure it can support the wattage of the LED work light. Using a light with higher wattage than the power supply can handle may result in electrical issues or potential damage. Similarly, using a light with lower wattage than needed may not provide sufficient brightness for your requirements.

By carefully assessing the power and wattage needs of the LED work light, you can ensure optimal performance and achieve the desired lighting levels for your specific tasks.

In a similar vein, my friend Mark recently purchased an LED work light for his garage. He initially chose a light with a lower wattage, thinking it would be sufficient for his needs. However, he soon realized that the light was not providing enough brightness for his projects. After doing some research and considering the power and wattage requirements, he upgraded to a higher wattage LED work light. The increased brightness made a significant difference in his workspace, allowing him to work more efficiently and with better visibility. Mark’s experience highlights the importance of carefully evaluating the power and wattage of an LED work light to ensure it meets your specific requirements.

Length and Gauge of the Wiring

When considering the length and gauge of the wiring for LED work lights, it is important to ensure proper functionality and safety. Using the appropriate wire gauge is crucial to prevent overheating and electrical hazards.

| Length and Gauge of the Wiring | Length of Wiring |

| 14 Gauge | Up to 15 feet |

| 12 Gauge | 15-30 feet |

| 10 Gauge | 30-45 feet |

| 8 Gauge | 45-60 feet |

| 6 Gauge | 60-80 feet |

Using wires that are too thin for the length of the wiring can result in voltage drop, which can cause dimmer lighting and reduced performance. On the other hand, using wires that are too thick for a shorter length can be unnecessary and add unnecessary cost.

It is recommended to consult the manufacturer’s guidelines or consult a professional electrician to determine the appropriate wire gauge for the specific length of wiring needed for your LED work lights.

Vehicle’s Electrical System

When considering whether a relay is needed for LED work lights, it is important to take into account the vehicle’s electrical system. Here are some factors to consider:

- Electrical capacity: Check if the vehicle’s electrical system can handle the additional power required by the LED work lights. Ensure that the alternator and battery are capable of supplying enough electricity to power the lights without causing any strain on the system.

- Wiring compatibility: Verify if the existing wiring in the vehicle is compatible with the LED work lights. Ensure that the wiring gauge is appropriate for the power requirements of the lights. If the gauge is too small, it may lead to overheating or malfunctioning of the lights.

- Protection: Consider the protection of the vehicle’s electrical system. A relay can act as a safeguard by preventing excessive current from flowing through the vehicle’s switches and wiring. This can help protect the switches and prevent them from getting damaged due to overloading.

When considering whether a relay is needed for LED work lights, it is essential to evaluate the vehicle’s electrical system. This includes taking into account the electrical capacity of the system, the compatibility of the existing wiring, and the overall protection of the system. By ensuring that the electrical system can handle the additional power required, verifying the wiring compatibility, and considering the benefits of a relay for protection, you can make an informed decision regarding the use of LED work lights.

Enhanced Performance and Efficiency

When it comes to achieving enhanced performance and efficiency in LED work lights, there are several crucial factors that you should keep in mind:

- Quality of LED: The performance and efficiency of LED work lights highly depend on the quality of the LEDs used. To ensure optimal performance, it is advisable to choose lights that utilize high-quality LEDs.

- Energy Consumption: LED work lights are renowned for their remarkable energy efficiency. They consume significantly less energy than traditional lighting options, making them an excellent choice for achieving enhanced performance while reducing energy costs.

- Brightness: The brightness of LED work lights is measured in lumens. Greater lumens indicate higher brightness levels, which can significantly enhance performance in various work environments. Therefore, it is essential to consider the brightness requirements of your specific tasks when selecting a light.

- Durability: LED work lights are thoughtfully designed to be robust and long-lasting. They are resistant to shocks, vibrations, and extreme temperatures, ensuring reliable performance even in challenging working conditions.

- Adjustability: Some LED work lights come with adjustable settings that allow you to customize the brightness and focus of the light beam based on your specific needs. This adaptability enhances performance and efficiency by providing optimal lighting for different tasks.

By taking these factors into consideration, you can choose LED work lights that offer enhanced performance and efficiency, consequently improving productivity and reducing energy consumption.

Longevity of the LED Work Lights

The longevity of LED work lights can be enhanced by considering certain factors:

- Quality of components: LED work lights that are made with high-quality components are more likely to have a longer lifespan. Look for lights that use durable materials and are built to withstand harsh working conditions.

- Heat dissipation: Proper heat dissipation is crucial for ensuring the longevity of LED work lights. Lights that have efficient heat dissipation systems, such as heat sinks or fans, can prevent overheating and prolong the lifespan of the LEDs.

- Protection against water and dust: LED work lights that have a high IP (Ingress Protection) rating are more resistant to water and dust, ensuring that they continue to function properly even in challenging environments.

- Optimal usage: Using LED work lights within their recommended voltage range and operating temperatures can help increase their longevity. It is important to avoid overloading or exceeding the specified limits to prevent damage to the lights.

- Regular maintenance: Performing regular maintenance on LED work lights, such as cleaning the lenses and checking for any signs of damage or wear, can help identify issues early on and prevent them from worsening.

Fact: LED work lights have an average lifespan of around 50,000 to 100,000 hours, which is significantly longer compared to traditional lighting options.

Some Facts About “Do LED Work Lights Need a Relay”:

- ✅ Using a relay switch is necessary when wiring up LED work lights with a large amp draw. (Source: Black Oak LED Blog)

- ✅ Relay switches prevent overheating of ordinary switches, burning up of wires, and ensure proper electrical flow. (Source: Black Oak LED Blog)

- ✅ For LED work lights with small amp draw, a relay switch may not be needed. (Source: Black Oak LED Blog)

- ✅ Wiring the relay switch involves connecting prongs to the battery, LED light, power source, and ground. (Source: Black Oak LED Blog)

- ✅ Assistance is available for any queries regarding the wiring process of LED work lights with a relay switch. (Source: Black Oak LED Blog)

Frequently Asked Questions

Do LED work lights need a relay?

LED work lights may or may not require a relay, depending on their amperage power. Smaller LED pods or rock lights with a low amp draw may not need a relay. However, larger LED light bars, such as double row or single row light bars, typically require a relay switch to prevent overheating and ensure proper electrical flow.

What is a relay switch?

A relay switch is an electronic switch that allows a low-current circuit to control a high-current circuit. It helps regulate the flow of electricity and prevents issues like overheating, wire burning, and electrical fires. In the context of LED light bars, a relay switch ensures the safe and efficient operation of the light by controlling the high amount of current required.

Why is a relay switch important for LED light bars?

A relay switch is important for LED light bars because it helps protect the electrical system from potential damage. The high amp draw of larger light bars can overload regular switches, causing them to overheat and potentially melt or burn wires. By using a relay switch, the high current is controlled separately, reducing the risk of electrical issues and ensuring the longevity of the light bar.

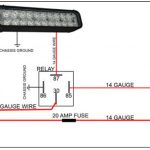

How do I wire a relay switch for an LED light bar?

To wire a relay switch for an LED light bar, start by connecting the positive terminal of the battery or a power source (that only receives power with the ignition turned on) to the “30” prong of the relay. Then, connect the positive side of the LED light to the “87” prong of the relay. Next, connect the power source used to control the LED light bar (e.g., high beam wire or backup wire) to the “86” prong of the relay. Finally, connect the “85” prong of the relay to a ground. If you have any specific questions or need step-by-step guidance, our experienced staff is available to assist you.

What gauge wire should I use for a 300-watt light bar?

When installing a relay for a 300-watt light bar, it is recommended to use 14 gauge wire. This gauge of wire is capable of handling the appropriate amount of current without experiencing voltage drop or overheating. Using the correct gauge wire ensures the relay and light bar operate safely and efficiently.

Can I use a separate switch to control my LED light bar without a relay?

Yes, it is possible to use a separate switch to control your LED light bar without a relay. However, there are a few important considerations. Firstly, the light bar should not be directly connected to the battery but on a separate circuit with an appropriate amperage switch. Additionally, it is crucial to avoid using high beams or other lower voltage switches to control the light bar, as this can pose the risk of electrical fires. If you have any doubts or questions about your specific setup, it is recommended to consult with our experienced staff for clarification and guidance.

.jpg)

.jpg)

.jpg)