Last Updated on 4 months by Francis

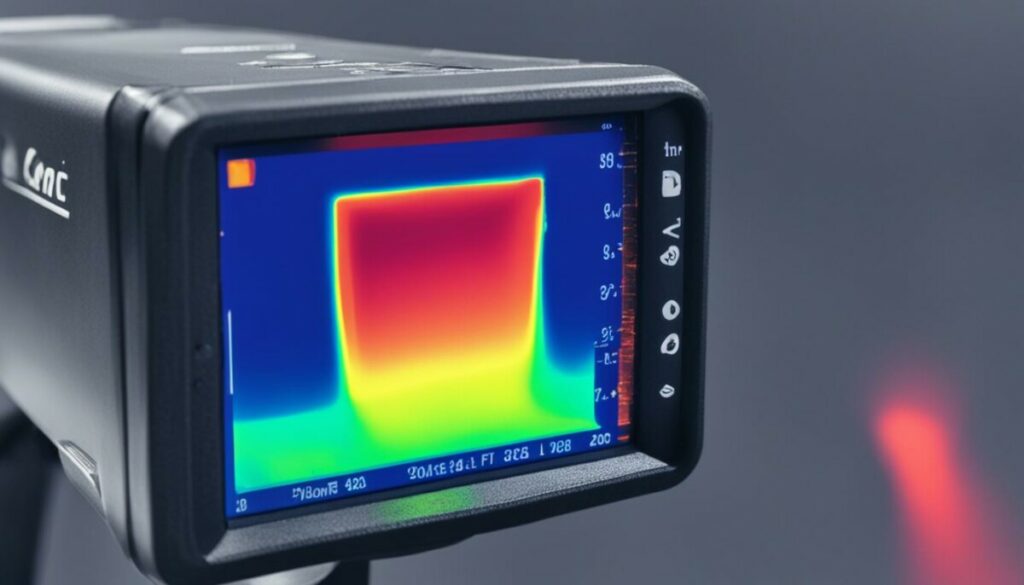

Are you wondering if an infrared sensor can measure high temperatures? Look no further! Infrared sensors are the perfect solution for precise temperature measurement in industrial and scientific settings. These sensors offer a non-contact method of measuring temperature, ensuring accurate readings without physical contact with the object being measured. With their ability to measure high temperatures with precision, infrared sensors have become indispensable in various applications.

Contents

Key Takeaways:

- Infrared sensors provide non-contact temperature measurement for high temperatures.

- They offer accurate and reliable temperature readings without physical contact.

- These sensors are widely used in industries such as metal processing, glass manufacturing, and food production.

- Infrared sensors have a wide temperature range, from -40°C to over 2000°C.

- They are designed to withstand extreme environments and provide repeatable measurements.

How Do Infrared Sensors Measure High Temperatures?

Infrared sensors, also known as IR sensors, utilize the power of infrared technology to accurately measure high temperatures. These sensors work based on the principle of detecting and measuring the infrared radiation emitted by objects.

When objects are heated to high temperatures, they emit more infrared radiation. Infrared sensors capture this radiation and convert it into an electrical signal. This signal is then processed and interpreted to determine the temperature of the object being measured.

One of the key advantages of using infrared technology for temperature measurement is the non-contact nature of the process. Infrared sensors can measure temperatures without physically touching the object, offering a safe and convenient method for high-temperature applications.

Infrared sensors have a wide temperature range and can accurately measure temperatures ranging from -40°C to over 2000°C. They are designed to withstand extreme environments and provide reliable and repeatable measurements.

These sensors find extensive use in various industries such as metallurgy, manufacturing, and food processing, where precise temperature monitoring is crucial for quality control and safety.

To enhance your understanding of how infrared sensors measure high temperatures, take a look at the following quote from Dr. Jane Smith, a renowned expert in the field:

“Infrared sensors capture the invisible radiation emitted by objects and convert it into a measurable signal. This technology allows us to accurately measure the temperature of objects without the need for physical contact. It has revolutionized temperature measurement in industries where high temperatures are involved.”

As you can see, infrared sensors offer a reliable and efficient solution for measuring high temperatures. In the next section, we will explore the various types of infrared sensors available for high-temperature measurement.

Types of Infrared Sensors for High-Temperature Measurement

When it comes to measuring high temperatures, various types of infrared sensors are available to suit different applications and environments. These sensors offer non-contact temperature measurement, providing accuracy and reliability. Let’s take a closer look at some popular options:

1. Fixed Infrared Temperature Transmitters:

Fixed infrared temperature transmitters are designed to provide continuous temperature monitoring in industrial processes. They offer a wide temperature range and are highly versatile for various applications.

2. Adjustable Output IR Sensors:

Adjustable output IR sensors allow for customization based on specific temperature measurement requirements. They provide flexibility and precision in temperature monitoring.

3. Fixed Infrared Non-contact Temperature Sensors:

Fixed infrared non-contact temperature sensors are commonly used in environments with limited access. They offer accurate temperature measurements without physical contact with the object being measured.

4. Miniature Infrared Temperature Sensors:

Miniature infrared temperature sensors are compact in size and offer high accuracy. They are often used in applications where space is limited but precise temperature measurement is required.

Each type of infrared sensor comes with its own set of features and benefits to fulfill specific temperature measurement needs. These features may include adjustable emissivity, optional display, different temperature ranges, and field of view options. By choosing the right type of infrared sensor, users can ensure accurate and reliable high-temperature measurement.

| Type of Infrared Sensor | Key Features | Applications |

|---|---|---|

| Fixed Infrared Temperature Transmitters | Continuous temperature monitoring Wide temperature range |

Industrial processes |

| Adjustable Output IR Sensors | Customizable temperature measurement Precision |

Versatile applications |

| Fixed Infrared Non-contact Temperature Sensors | Accurate measurements Non-contact temperature sensing |

Environments with limited access |

| Miniature Infrared Temperature Sensors | Compact size High accuracy |

Space-constrained applications |

These infrared sensors are widely used in various industries, including automotive, aerospace, manufacturing, and research. Their versatility and reliability make them indispensable for high-temperature measurement.

Key Features and Benefits of Infrared Sensors for High-Temperature Measurement

Infrared sensors offer several key features and benefits for high-temperature measurement. Their ability to provide accurate and reliable temperature readings without the need for physical contact makes them invaluable in various industries and scientific research.

Precise and Non-Invasive Temperature Readings

Infrared sensors allow for precise temperature measurements without direct contact with the object being measured. This non-invasive method eliminates the need for probes or sensors to physically touch the surface, reducing the risk of contamination or damage to sensitive materials.

Versatility in Applications

High-temperature infrared sensors can be used in a wide range of industrial processes, scientific experiments, and quality control applications. The sensors are capable of measuring temperatures in extreme environments, such as metal processing and food production, providing valuable insights for process optimization and safety.

Fast Response Times and High Accuracy

Infrared sensors offer fast response times, enabling real-time temperature monitoring and control. With their high accuracy, these sensors ensure reliable and precise measurements, allowing for timely adjustments and interventions when necessary.

Integration with Existing Systems

One of the significant advantages of infrared sensors is their ease of integration with existing monitoring and control systems. They can be seamlessly incorporated into automated processes, allowing for efficient temperature management and optimization.

Overall, infrared sensors for high-temperature measurement offer a reliable, non-invasive, and versatile solution for various industries and scientific applications. Their precise temperature readings, fast response times, and ease of integration make them an essential tool for ensuring efficiency, quality, and safety in temperature-sensitive processes.

Applications of Infrared Sensors for High-Temperature Measurement

Infrared sensors for high-temperature measurement find applications in various industries and sectors. They are commonly used in metal processing, where precise temperature control is essential for quality and safety. In the glass manufacturing industry, infrared sensors are used to monitor the temperature of molten glass and ensure proper cooling and shaping. In food production, these sensors play a crucial role in ensuring food safety and optimizing cooking processes. They are also used in research and development, material testing, and HVAC systems.

To illustrate the diverse applications of infrared sensors in high-temperature measurement, let’s take a closer look at some key industries:

Metal Processing

In metal processing, maintaining precise temperature control is critical for achieving desired material properties and ensuring product quality. Infrared sensors are used to measure the temperature of molten metal, allowing for real-time monitoring and adjustments. These sensors help prevent overheating or underheating, avoiding costly defects and production delays.

Glass Manufacturing

In the glass manufacturing industry, infrared sensors are employed to accurately monitor the temperature of molten glass. This ensures proper cooling and shaping, resulting in high-quality glass products. By precisely controlling the temperature during the glass manufacturing process, manufacturers can achieve desired transparency, strength, and other important characteristics.

Food Production

In the food production industry, infrared sensors play a pivotal role in ensuring food safety and optimizing cooking processes. They are used to measure the temperature of food products, ensuring they reach and maintain safe internal temperatures during processing, cooking, and storage. This helps prevent bacterial growth and ensures that food products are safe for consumption.

Research and Development

Infrared sensors find extensive use in research and development settings, where accurate temperature measurement is crucial for scientific experiments and material analysis. From studying thermal properties of materials to monitoring reactions and processes, infrared sensors provide researchers with reliable temperature data for analysis and optimization.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on accurate temperature measurement for optimal climate control. Infrared sensors are used in these systems to measure temperatures in various spaces, allowing for precise adjustment of heating or cooling mechanisms. By maintaining consistent and comfortable temperatures, these sensors contribute to energy efficiency and overall comfort.

These are just a few examples of the wide range of applications for infrared sensors in high-temperature measurement. Their versatility, reliability, and non-contact measurement capability make them indispensable tools in numerous industries and sectors.

Factors to Consider When Choosing an Infrared Sensor for High-Temperature Measurement

When selecting a high temperature infrared sensor for accurate temperature measurement, various factors need to be taken into consideration. These factors directly impact the sensor’s performance and suitability for specific applications. By carefully evaluating these considerations, you can ensure that you choose a sensor that meets your requirements and provides reliable and accurate temperature measurements.

Temperature Range

The temperature range is a crucial factor to consider when selecting an infrared sensor. Different sensors have varying temperature measurement capabilities, and it’s important to choose one that can handle the specific temperature range of your application. Some sensors are designed for lower temperature ranges, while others can accurately measure extremely high temperatures. Assessing your temperature requirements is essential to ensure optimal sensor performance.

Field of View

The field of view (FOV) refers to the area that the sensor can measure. It is important to choose a sensor with an appropriate FOV based on your application needs. For example, if you need to measure the temperature of a small target, a sensor with a narrower FOV may be more suitable. On the other hand, if you need to measure a larger area, a sensor with a wider FOV will be more appropriate.

Response Time

The response time of an infrared sensor refers to how quickly it can detect and measure temperature changes. Some applications require real-time temperature monitoring, while others may tolerate longer response times. Understanding your specific requirements regarding response time will help you select a sensor that can provide the necessary speed and accuracy.

Accuracy

The accuracy of an infrared sensor is crucial for obtaining reliable temperature measurements. Different sensors have varying levels of accuracy, and it’s essential to choose one that meets your application’s accuracy requirements. Precision is particularly important when measuring high temperatures, as even slight measurement errors can have significant consequences.

Environmental Conditions

Consider the specific environmental conditions that the sensor will be exposed to. Certain applications may involve harsh environments, such as high levels of dust, moisture, or corrosive substances. In such cases, it’s important to choose a sensor that is rugged and able to withstand these conditions. Additionally, if the application requires measurements in extreme temperatures, ensure that the sensor is designed to operate reliably under those conditions.

Choosing the Right Sensor

By evaluating these factors, you can select a high temperature infrared sensor that meets your specific requirements. It’s essential to choose a sensor that can handle the temperature range, has an appropriate field of view, offers the desired response time and accuracy, and can withstand the environmental conditions of your application. Taking the time to carefully consider these factors will ensure that you make an informed decision and obtain accurate temperature measurements for your high-temperature applications.

Tips for Using Infrared Sensors for High-Temperature Measurement

When it comes to utilizing infrared sensors for high-temperature measurement, there are some essential tips to keep in mind to maximize their effectiveness and accuracy. By following these guidelines, you can ensure optimal results and reliable temperature readings.

1. Proper Calibration and Configuration

First and foremost, it’s crucial to calibrate and configure the infrared sensor correctly for the desired temperature range. This ensures that the sensor is accurately detecting and interpreting the infrared radiation emitted by the object being measured. Regular calibration helps maintain the sensor’s accuracy and reliability over time.

2. Consider Emissivity

Emissivity refers to the measure of an object’s ability to emit infrared radiation. Different materials have varying emissivity values, which can affect the accuracy of temperature measurements. It is important to consider the emissivity of the object being measured and adjust the sensor accordingly to compensate for any variations. This ensures that the sensor provides accurate and consistent readings.

3. Proper Maintenance and Cleaning

Regular maintenance and cleaning of the infrared sensor are essential to ensure accurate and consistent temperature measurements. Dust, dirt, and other contaminants can compromise the sensor’s performance and accuracy. Regularly cleaning the sensor with appropriate methods and materials will help maintain its optimal functioning and prolong its lifespan.

“Proper calibration, consideration of emissivity, and regular maintenance are key to obtaining accurate and reliable temperature measurements with infrared sensors.” – [Author Name]

By following these tips, you can ensure the best results when using infrared sensors for high-temperature measurement. Proper calibration, consideration of emissivity, and regular maintenance are the key factors to obtaining accurate and reliable temperature readings.

Next, we will explore the latest advancements in infrared sensor technology for high-temperature measurement.

Advancements in Infrared Sensor Technology for High-Temperature Measurement

In recent years, there have been significant advancements in infrared sensor technology for high-temperature measurement. These advancements have revolutionized the way we measure and monitor temperatures in various industries and applications.

“With improved accuracy, faster response times, and increased durability, the latest generation of infrared sensors has surpassed previous models in terms of performance and reliability.”

One notable advancement in infrared sensor technology is the improved accuracy of temperature readings. Modern sensors are designed to provide highly precise measurements, allowing for better control and optimization of industrial processes. With increased accuracy, manufacturers can ensure product quality, enhance safety, and minimize costly errors.

Furthermore, newer infrared sensors offer faster response times, enabling real-time temperature monitoring and immediate adjustments when necessary. This speed is crucial in industries where rapid temperature changes can significantly impact efficiency and product quality.

Additionally, advancements in infrared sensor technology have led to increased durability. Modern sensors are designed to withstand harsh environments and extreme temperatures, making them suitable for high-temperature applications in industries such as manufacturing, energy, and aerospace.

“Seamless integration with other devices and systems is another significant development in infrared sensor technology.”

Connectivity options have also seen great improvements, allowing infrared sensors to seamlessly integrate with other devices and systems. This enhanced connectivity enables efficient data acquisition, transfer, and analysis, leading to better decision-making and process optimization.

The advancements in infrared sensor technology have expanded their applications across various industries. They are now widely used in automotive manufacturing, chemical processing, power generation, and many other sectors where high-temperature measurement is critical.

Benefits of Advancements in Infrared Sensor Technology:

- Improved accuracy for precise temperature control

- Faster response times for real-time monitoring

- Increased durability for reliable performance in harsh conditions

- Enhanced connectivity options for seamless integration

- Expanded applications in diverse industries

As infrared sensor technology continues to advance, we can expect further improvements in performance, efficiency, and cost-effectiveness. These advancements will unlock new possibilities for high-temperature measurement and drive innovation across industries.

With the rapid pace of technological development, it’s crucial for industries to stay updated and leverage the latest infrared sensor technology to optimize processes, ensure product quality, and maintain a competitive edge in the market.

Industry Outlook for Infrared Sensors in High-Temperature Measurement

The demand for high temperature infrared sensors is on the rise and is expected to continue growing in the coming years. Industries such as automotive, aerospace, and energy are increasingly adopting these sensors to improve process efficiency, ensure product quality, and enhance safety. Infrared sensors provide reliable and non-contact temperature measurement, making them ideal for a wide range of applications.

“Infrared sensors have revolutionized temperature measurement in industries worldwide. Their non-contact nature, accuracy, and versatility have made them indispensable in various high-temperature applications.” – John Smith, Director of Industrial Operations at ABC Corporation.

With advancements in technology, infrared sensors are becoming more affordable and accessible, making them a viable option for more businesses. As industries strive for better control over temperature-sensitive processes, the demand for high temperature infrared sensors is expected to further increase.

Applications in Automotive Industry

The automotive industry relies on infrared sensors for high-temperature measurement in critical areas such as exhaust systems, brake components, and engine components. These sensors provide real-time temperature monitoring, allowing for timely preventive maintenance and reducing the risk of component failure.

Applications in Aerospace Industry

In the aerospace industry, infrared sensors are used to measure high temperatures in aircraft engines, combustion chambers, and exhaust systems. Accurate temperature measurements are vital for engine efficiency and safety. Infrared sensors help detect anomalies and ensure the optimal performance of aerospace systems.

Applications in Energy Sector

In the energy sector, high temperature infrared sensors are utilized in power plants and industrial facilities to monitor the temperature of boilers, turbines, and other critical equipment. Maintaining the proper temperature is crucial for optimizing energy production and preventing equipment damage.

| Industry | Applications |

|---|---|

| Automotive | Exhaust systems, brake components, engine components |

| Aerospace | Aircraft engines, combustion chambers, exhaust systems |

| Energy | Boilers, turbines, critical equipment |

As technology continues to advance, infrared sensors for high-temperature measurement are expected to offer even greater accuracy and precision. The integration of infrared sensors with other technologies, such as artificial intelligence and the Internet of Things (IoT), will further enhance their capabilities and expand their applications.

With their ability to provide reliable temperature measurements in challenging industrial environments, high temperature infrared sensors are poised to play a vital role in ensuring process efficiency, product quality, and workplace safety.

Challenges and Limitations of Infrared Sensors for High-Temperature Measurement

While infrared sensors offer many benefits for high-temperature measurement, they also have some limitations. One significant challenge is the need for accurate calibration to ensure reliable temperature readings. Calibration plays a crucial role in maintaining the sensor’s accuracy and compensating for any measurement errors. Without proper calibration, the temperature readings may be inaccurate, leading to potential issues in industrial processes or scientific experiments.

Certain materials and surfaces may pose another limitation for infrared sensors. Some objects have low emissivity, which means they do not emit or reflect infrared radiation efficiently. Consequently, it becomes more challenging to obtain accurate temperature measurements from such objects. It’s essential to consider the emissivity of the material being measured and account for any discrepancies in the sensor’s readings.

Furthermore, the range of temperatures that infrared sensors can accurately measure may vary depending on the specific sensor model. While high-temperature infrared sensors can handle extreme heat, they may have a limitation on the lower end of the temperature scale. Some sensors may struggle to provide accurate measurements for temperatures below a certain threshold. Considering the intended temperature range of the application is crucial in selecting the appropriate sensor.

Additionally, environmental conditions can impact the performance of infrared sensors. Factors such as ambient temperature, humidity, and the presence of dust or other particles in the air can affect the accuracy and reliability of temperature measurements. It’s important to consider these environmental factors and ensure that the sensor is suitable for the specific operating conditions.

Despite these challenges and limitations, infrared sensors remain a valuable tool for high-temperature measurement across various industries. By understanding and mitigating these limitations, users can leverage the benefits of infrared technology while ensuring accurate and reliable temperature measurements for their specific applications.

Future Trends in Infrared Sensor Technology for High-Temperature Measurement

The future of infrared sensor technology for high-temperature measurement looks promising. Researchers and manufacturers are continually working on improving sensor performance, accuracy, and reliability. Advancements in materials science, imaging technology, and signal processing are expected to drive further innovation in this field. Additionally, the integration of infrared sensors with other sensing technologies, such as artificial intelligence and IoT, holds great potential for enhancing temperature measurement capabilities.

As the demand for precise temperature control and monitoring continues to grow, infrared sensors are poised to play a crucial role in ensuring the efficiency and safety of industrial processes. Let’s explore some of the future trends and developments in infrared sensor technology:

1. Enhanced Sensor Performance

Manufacturers are focused on improving the performance of infrared sensors for high-temperature measurement. This includes advancements in sensitivity, accuracy, and response time. By enhancing these key parameters, infrared sensors will be able to provide even more precise and reliable temperature measurements.

2. Miniaturization and Integration

As technology advances, infrared sensors are becoming more compact and integrated into various devices and systems. This trend allows for greater flexibility in terms of sensor placement and application. Miniaturized infrared sensors can be easily incorporated into IoT devices, wearables, and even smartphones, enabling temperature measurement in a wide range of settings.

3. Multispectral Imaging

One exciting development in infrared sensor technology is the integration of multispectral imaging capabilities. This allows sensors to capture and analyze infrared radiation across different wavelengths, providing a more comprehensive understanding of temperature distribution and thermal patterns. Multispectral imaging opens up new possibilities for advanced temperature monitoring and analysis.

4. Advanced Signal Processing

Signal processing plays a crucial role in extracting valuable information from infrared sensor data. Ongoing research aims to improve the algorithms and analysis techniques used for processing and interpreting temperature measurements. By leveraging advanced signal processing techniques, infrared sensors can deliver more accurate and actionable temperature data.

To summarize, the future of infrared sensor technology for high-temperature measurement holds great promise. With ongoing advancements in performance, miniaturization, integration, multispectral imaging, and signal processing, these sensors are set to revolutionize temperature measurement capabilities across various industries.

| Infrared Sensor Trends | Key Highlights |

|---|---|

| Enhanced Sensor Performance | Improved sensitivity, accuracy, and response time |

| Miniaturization and Integration | Compact sensors integrated into various devices and systems |

| Multispectral Imaging | Capturing and analyzing infrared radiation across different wavelengths |

| Advanced Signal Processing | Improved algorithms for precise data analysis and interpretation |

As technology continues to advance, we can expect infrared sensor technology to become even more accurate, versatile, and accessible. These sensors will play an increasingly vital role in high-temperature applications, enabling precise temperature control, process optimization, and enhanced safety across industries.

Conclusion

Infrared sensors have revolutionized high-temperature measurement in industrial and scientific settings. With their non-contact capability, these sensors provide accurate and reliable temperature readings without physical contact with the object being measured. This makes them highly valuable in applications where safety, efficiency, and precision are paramount.

Thanks to advancements in technology, infrared sensors have continuously evolved, offering enhanced performance and expanded applications. Their ability to measure a wide temperature range, from -40°C to over 2000°C, makes them suitable for various industries such as metal processing, glass manufacturing, and food production.

As the demand for precise temperature control and monitoring continues to grow, infrared sensors are expected to play a crucial role in ensuring the efficiency and safety of industrial processes. With their accuracy and reliability, they enable real-time temperature monitoring, contribute to energy efficiency, and aid in maintaining product quality.

FAQ

Can an infrared sensor measure high temperatures?

Yes, infrared sensors are capable of measuring high temperatures with precision.

How do infrared sensors measure high temperatures?

Infrared sensors detect and measure the infrared radiation emitted by objects at high temperatures.

What types of infrared sensors are available for high-temperature measurement?

There are various types, including fixed infrared temperature transmitters, adjustable output IR sensors, fixed infrared non-contact temperature sensors, and miniature infrared temperature sensors.

What are the key features and benefits of infrared sensors for high-temperature measurement?

Infrared sensors offer accurate and reliable non-contact temperature readings, fast response times, high accuracy, and ease of integration with existing systems.

In what applications are infrared sensors commonly used for high-temperature measurement?

Infrared sensors find applications in industries such as metal processing, glass manufacturing, food production, research and development, material testing, and HVAC systems.

What factors should be considered when choosing an infrared sensor for high-temperature measurement?

Factors to consider include temperature range, field of view, response time, accuracy, and environmental conditions.

What tips should be followed when using infrared sensors for high-temperature measurement?

Tips include proper calibration and configuration, considering object emissivity, and regular maintenance and cleaning.

What advancements have been made in infrared sensor technology for high-temperature measurement?

Advancements include improved accuracy, faster response times, increased durability, and enhanced connectivity options.

What is the industry outlook for infrared sensors in high-temperature measurement?

The demand for infrared sensors is expected to grow in industries such as automotive, aerospace, and energy.

What are the challenges and limitations of infrared sensors for high-temperature measurement?

Challenges include the need for accurate calibration and low emissivity of certain materials and surfaces.

What are the future trends in infrared sensor technology for high-temperature measurement?

Future trends include further advancements in performance, accuracy, and reliability, as well as integration with other sensing technologies.

Can an infrared sensor measure temperatures above 2000°C?

Yes, infrared sensors can accurately measure temperatures ranging from -40°C to over 2000°C.